Custom Acrylic Sheets

Acrylic Sheet Customization options

Customizing CLAREX: Tailored Solutions for Your Unique Needs

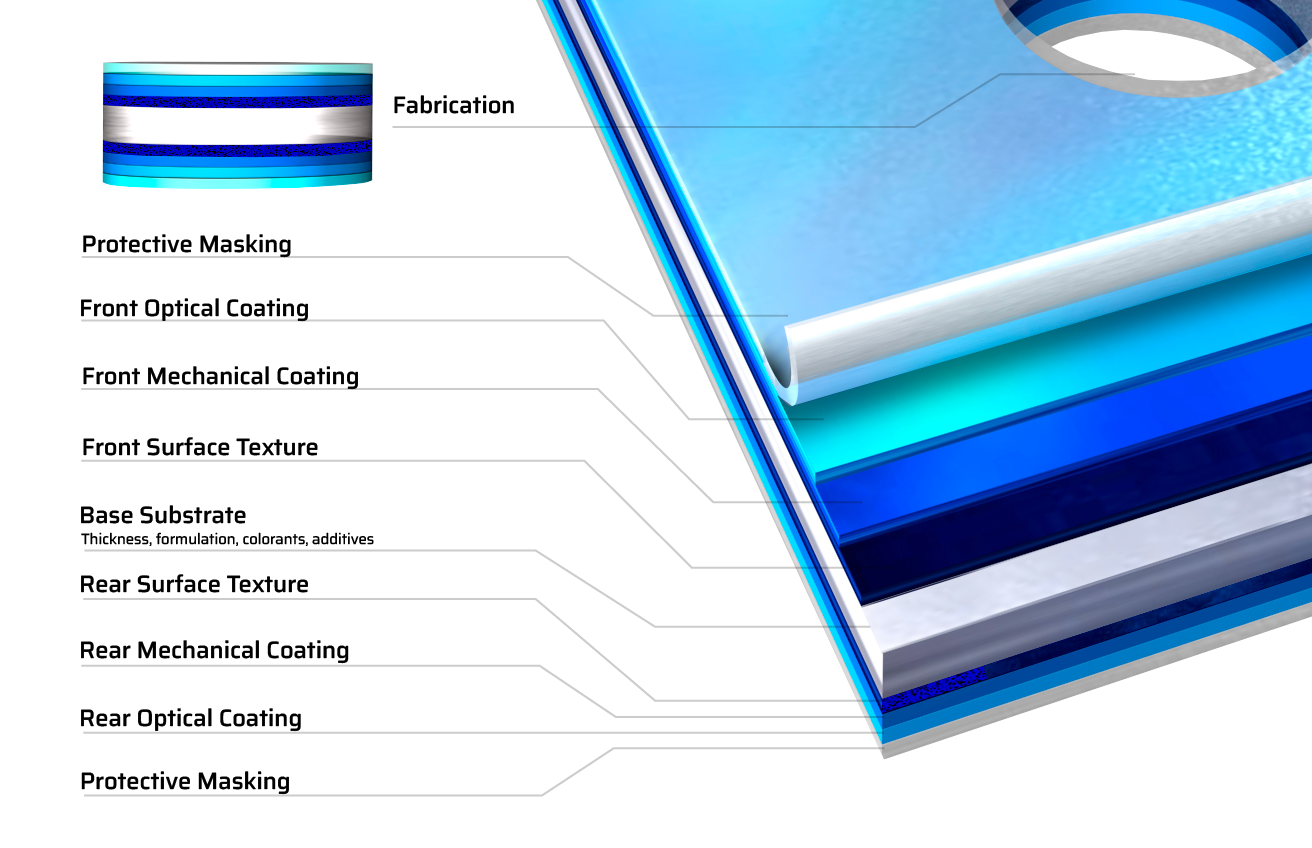

CLAREX cell-cast acrylic sheets offer unparalleled flexibility through a wide range of customization options, allowing you to create materials perfectly suited to your specific applications.

From selecting the ideal base formulation to adding specialized layers for enhanced performance or aesthetics, every detail can be tailored to your requirements. Whether you need anti-reflective coatings, UV resistance, or diffusive features, our customization options ensure you get the perfect solution for your project.

Step 1: Choose the Base Substrate for Your Custom Acrylic Sheet

Choose the right starting point for your custom acrylic sheet, ensuring it is optimized for performance, appearance, and specialized functionality.

CLAREX offers many customization options, many of which can be combined.

- Formulation Options

- Standard PMMA formulation (default)

- UV-blocking for reduced UV transmission

- UV-transmitting (UVT) for increased UV transmission

- HiTemp for higher heat resistance

- Low moisture absorption

- Color Options

- Transmissive colors

- Neutral density (smoke)

- Translucent colors

- Opaque colors

- NIR (high-pass)

*If we don’t already have the color you need, color-matching is available

- Additives

- Light-scattering particles for diffusion

- Light-scattering particles for light guides

- Custom particles for creating rear projection screens

Step 2: Choose the Surface Texture Layer

CLAREX offers a range of non-glare textures, with the option to apply different textures on each side of the sheet.

- Glossy/Smooth Surface (default)

- Fully transparent with optics-quality clarity and extremely low surface roughness

- High-Gloss Textures

- Imparts minimal haze; often barely noticeable

- Commonly used to eliminate Newton Rings

- Medium-Gloss Textures

- Appears hazy when viewing through the material, but minimal impact when placed close to a display

- Diffuses Reflections – Ideal for anti-glare (AG) front panels or windows on flat panel displays

- Low-Gloss Textures

- Very hazy, even when held up against a display

- Used for light diffusion applications

Step 3: Choose Mechanical Surface Coatings

CLAREX mechanical surface coatings are applied in-mold, a unique CLAREX capability, resulting in coatings that maintain the optical clarity of the base substrate. Different coatings can be applied to each side for added flexibility.

- No Surface Coating

- Ideal if coating isn’t needed or desired

- Suitable for applications requiring printing or bonding to the surface

- Standard Hard-Coat

- Improves scratch and chemical resistance

- UV-stable for outdoor use

- Can be applied to textured surfaces without compromising texture

- Super Hard-Coat

- Offers a slight boost in scratch resistance compared to the standard hard-coat

- Anti-Bacterial Hard-Coat

- Contains anti-bacterial ingredients to inhibit surface bacteria

Step 4: Choose Optical Coatings

Optical coatings are typically added as a secondary process, most often through vacuum deposition. Other application methods are available depending on your needs. Coatings can be stacked or applied differently on each side for added functionality.

- Standard Anti-Reflective (AR) Coatings

- Tuned for the visible range

- Requires a standard hard-coat as a base

- Custom-Tuned Anti-Reflective Coatings

- Can be optimized for near infrared (NIR) applications

- Can be optimized for ultraviolet (UV) applications

- Anti-Smudge (Oleophobic) Coatings

- Creates an easy-to-clean surface

- The vacuum deposition coatings are susceptible to fingerprints and smudges, so the anti-smudge coating is commonly applied in conjunction

- NIR-Block Coatings (Low-Pass)

- Commonly used in night vision imaging system (NVIS) applications

- Can be used for heat reduction and hot mirror applications

- Mirror Coatings

- Available as 1st or 2nd surface mirror coatings

- Customizable transmission and reflection levels

- Colored mirror options available

Step 5: Customize Your Acrylic Sheet’s Size & Format

CLAREX acrylic sheets are available in a range of thicknesses and formats, from full sheets to fully finished parts ready for installation.

- Thickness

- Available from 0.2 mm to 5.0 mm thick

- Dependent on material configuration

- Sheet Size

- Available from 290×360 mm up to 1000×1000 mm

- Dependent on material configuration

- Protective Masking

- Poly masking on front and back (default)

- Paper masking is available

- Finished Parts

- CNC laser cutting for 2-dimensional parts

- CNC machining for 2.5-dimensional parts, such as step cuts, pockets, bevels, etc

- Adhesive application

- Custom-printed parts available