CLAREX Anti-Reflective, Coated Acrylic (AR, MH)

Optical coatings for increased transmission and reduced reflection.

CLAREX Anti-Reflective (AR) Coated Filters have a multi-layer AR coating which reduces reflections. The decreased reflection results in increased transmission. The sheets are Hard-coated prior to applying the AR coatings thus increasing the scratch and chemical resistance of the sheets as well.

An oleophobic Anti-Smudge coating could be added to the anti-reflective coated surfaces. While this additional coating will not prevent fingerprints and smudges, it makes it much easier to clean them off.

The AR coatings could be combined with non-glare textured surfaces to further reduce glare and reflection.

Learn More about Anti-Reflective vs Non-Glare

The standard AR coating is designed for the visible range. However, the AR coating design could be customized, such as for applications in the NIR and UV ranges.

Benefits

- Optical Grade Filters – 100% visually inspected for defects

- Excellent transmission, greater than 98% in the visible (or design) range

- Excellent surface hardness

- Anti-smudge coating makes the surface easier to clean (but cannot ‘prevent’ fingerprints)

- AR available one side or two sides with or without anti-smudge coating

- Available with custom-tuned anti-reflective coating

- Excellent machinability and laser-cutting performance

- Can be customized

- If we don’t already have the color you need, color-matching is available

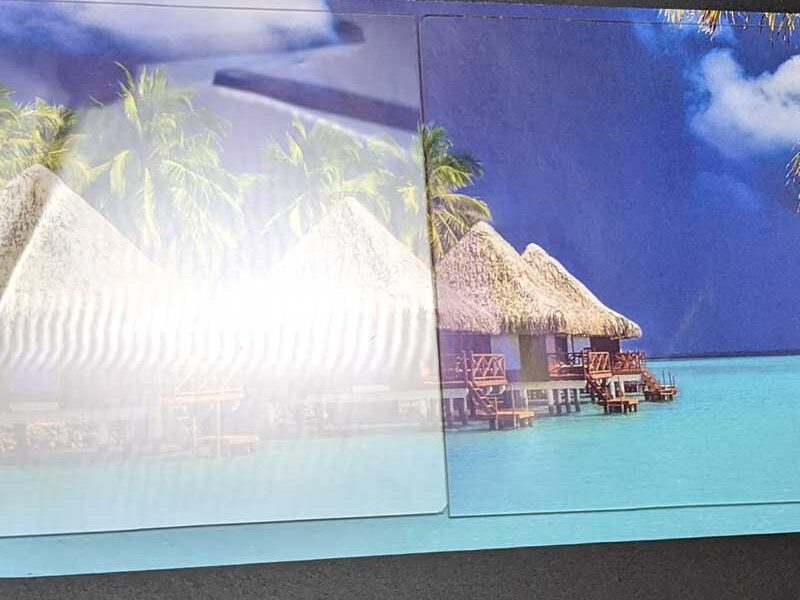

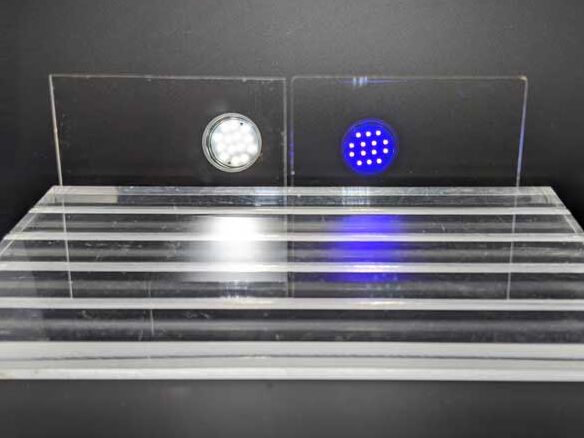

UNCOATED vs. AR COATED under a bright light

Reflection of a very bright light source. The sample on the right (with blue reflection) has AR coating. Reflection intensity is much lower.

Common Anti-Reflective Acrylic Applications

- Protective window for flat panel displays

- Sunlight readable displays

- Barcode scanner exit windows

- Camera enclosure windows

- Machine vision

- Sensor windows

Thicknesses

- 0.2mm

- 0.25mm

- 0.3mm

- 0.35mm

- 0.4mm

- 0.5mm

- 0.6mm

- 0.7mm

- 0.8mm

- 1.0mm

- 1.2mm

- 1.5mm

- 2.0mm

- 2.5mm

- 3.0mm

- 3.5mm

- 4.0mm

- Custom

Sheet Size

- 290 x 360mm Coated area standard

- Custom sizes available upon request

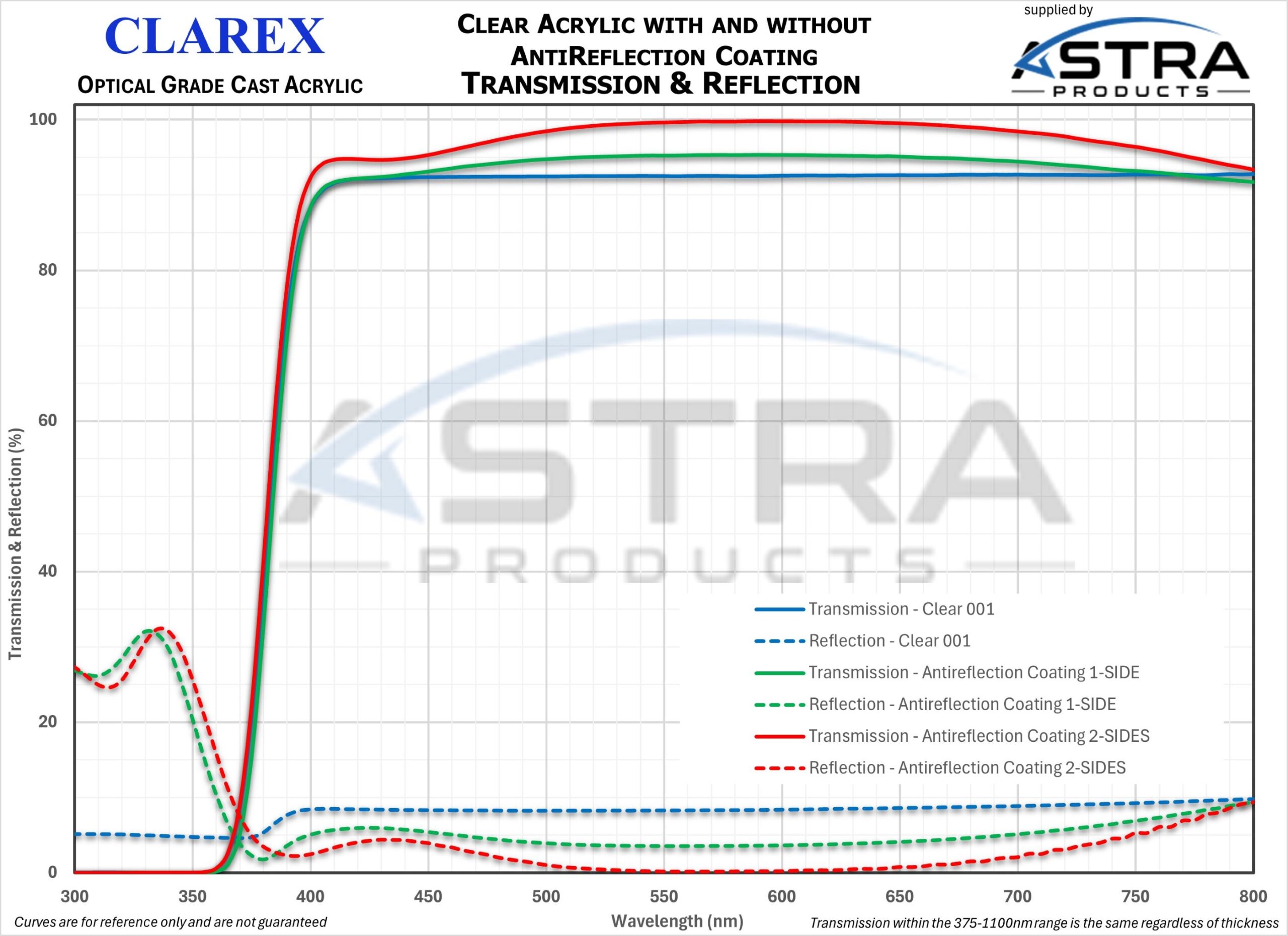

Transmission/Reflection Curves

Uncoated clear acrylic will reflect about 8% of incoming light. Half of the reflections come off the front (first) surface, and the other half come off the rear (second) surface. AR coating applied on one side will eliminate about half the total reflections resulting in about 4% total reflection. When AR coating is applied on both sides, the total reflection is reduced to about 1%. These curves show the performance of clear acrylic with standard visible AR coating on one side and on two sides.

Customization

Custom sheets & parts to meet the needs of your applications.

Build your own sheets! Do you have a unique design requirement that cannot be met with off-the-shelf acrylic sheets? The CLAREX sheets can be fully customized and produced in low volumes up to mass production. Choose the thickness, formulation, additives, color dye/pigments, surface textures, surface coatings, and optical coatings for your custom material configuration, and we can typically have it ready for you in 4-8 weeks. We can even fabricate the finished parts for you.

Physical Properties of CLAREX Anti-Reflective Filters (AR Acrylic)

| PROPERTY | METHOD | UNIT | VALUE |

|---|---|---|---|

| Specific Gravity | ASTM D-792 | 1.19 | |

| Elongation | ASTM D-638 | % | 5 |

| Flexural Rupture Strength | ASTM D-790 | kg/cm2 | 800 |

| Heat Distortion Temperature | ASTM D-648 | °C | 110 |

| Maximum Recommended Continuous Temperature | °C | 80 | |

| *Available with higher temperature ratings upon request, 90-95°C | |||

| Coefficient of Thermal Expansion | ASTM D-696 | cm/cm/ºC | 7 x 10-5 |

| Heat Resistance | 80ºC x 100hr | No Change | |

| Cold Resistance | -40ºC x 100hr | No Change | |

| Humidity Resistance | 60ºC x 90% x 100hr | No Change | |

| Thermal Cycle | -40ºC <> 80ºC (10 cycles) | No Change | |

| Sunshine Weather Meter | 100hr | No Change | |

| Pencil Hardness | >6H | ||

| Contact Angle | 114º | ||

| CHEMICAL RESISTANCE | |||

| Isopropyl Alcohol (50%) | No Change | ||

| Soap Aqua Solution | No Change | ||

| Water | No Change | ||

| Sulfuric Acid | Dissolved | ||

| Sodium Carbonate | Dissolved | ||