CLAREX Hard-coated Polycarbonate Sheets (PC)

Hard-coated polycarbonate sheets with the quality you expect from CLAREX.

While the CLAREX factory’s main focus is manufacturing custom cast acrylic sheets, they have also been able to supply Clear Coated Polycarbonate sheets with the same attention to quality that they are known for. They start by sourcing high optical quality polycarbonate sheets from their partner in Japan. They then apply their acrylic-based UV-stable hard-coat for scratch and chemical resistance, with or without non-glare (AG) textured surfaces. They can also apply an anti-reflection (AR) coating.

Benefits

- High optical quality polycarbonate sheets

- Low birefringence

- Great for applications where acrylic isn’t acceptable

- Impact resistant

- Scratch and chemical resistant

- 1-2H pencil hardness

- UV-Stable

- Available with non-glare (AG) textures (see table)

- Available with anti-reflection coating

CLAREX Polycarbonate for applications requiring impact resistance

Applications

- LCD protective windows

- Camera and lens covers

- Sensor windows

- and more

Thicknesses

- 0.5mm

- 1.5mm

- 0.8mm

- 2.0mm

- 1.0mm

- Custom

Size

- 400 x 550mm is standard

- Please contact us to discuss standard and custom sheet size options.

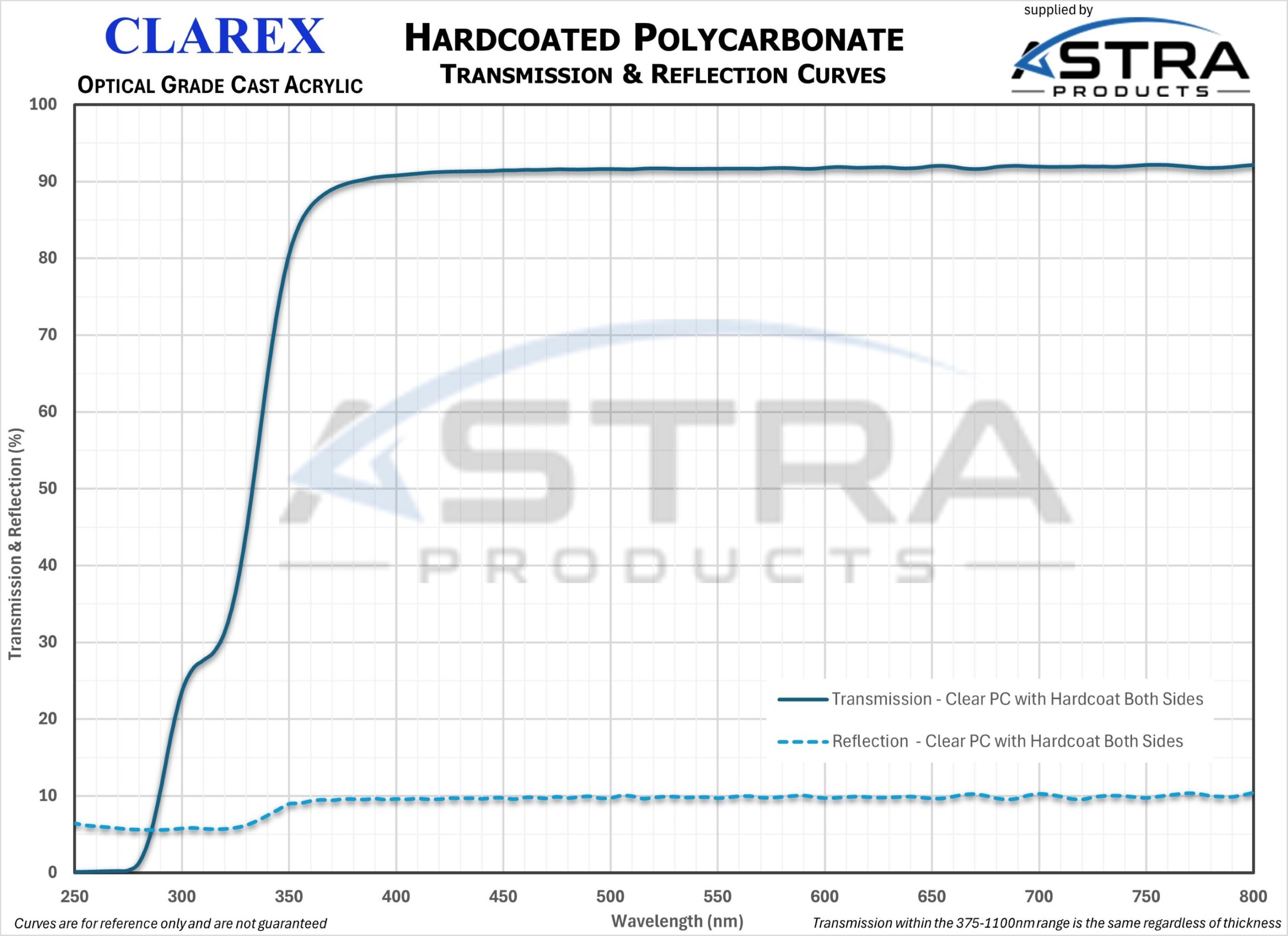

Transmission Curves

Available Non-Glare (AG) Textures

| NON-GLARE TYPE | ROUGHNESS OF SURFACE | PEAK COUNT AREA: 5MM | HAZE | GLOSS VOLUME |

|---|---|---|---|---|

| EX30 | 0.70~1.12µm | 180~250 | 7.0% | 45 |

| No.1 | 0.80~1.25µm | 60~100 | 1.9% | 55 |

| No.2 | 1.20~1.64µm | 70~110 | 6.3% | 35 |

| No.9 | 0.56~0.90µm | 45~100 | 1.0% | 78 |